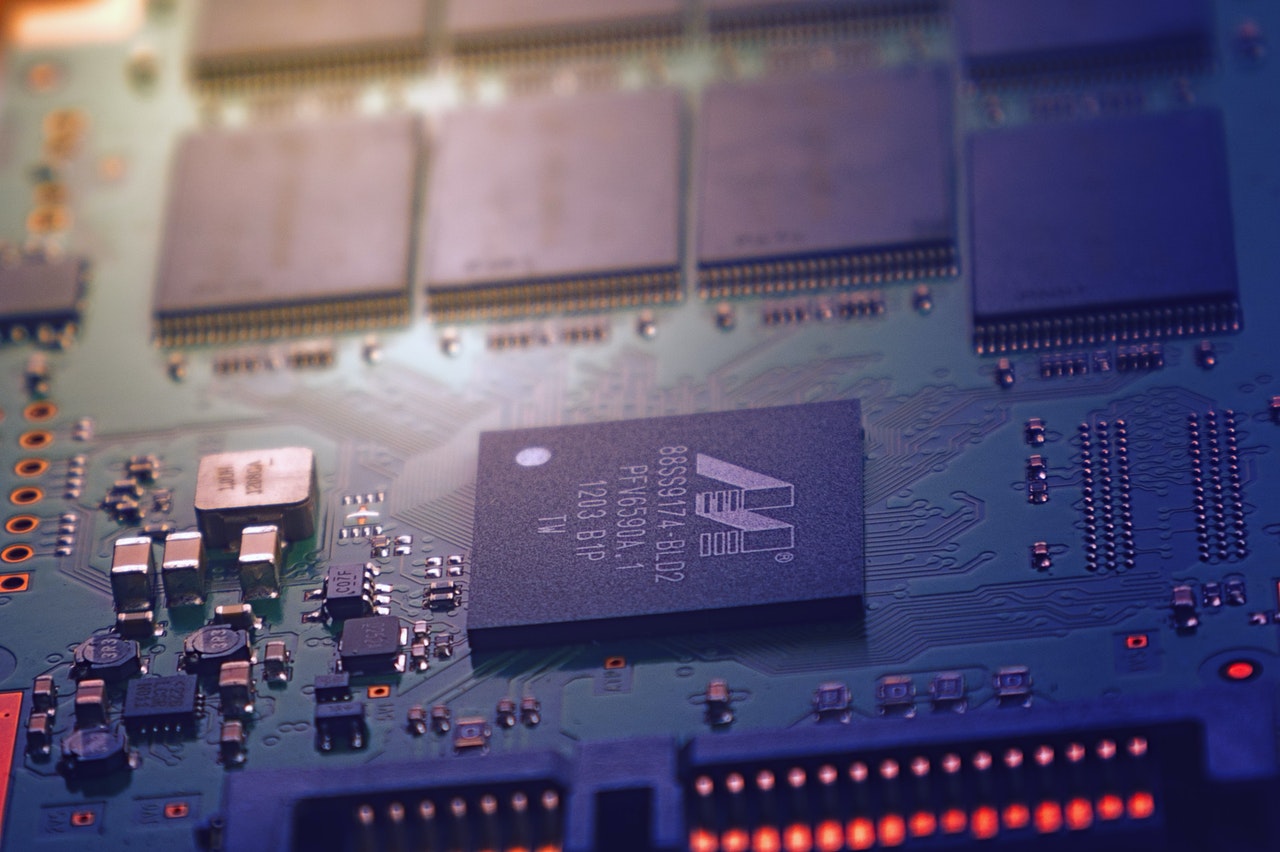

Electronics, gadgets, and other things people own often include several internal components that work together to offer the features and performance they need. For example, a mobile phone is more than just the case, buttons, and display you see on the exterior. Several sections house and connect the relevant components inside the device. Circuit boards are a critical component of any electronic device (PCB).

Printed circuit boards (PCBs) are used to build most electrical devices. The global PCB product sales value is estimated to reach $82 billion in the United States by 2018. This can be deduced from the frequency with which PCBs are employed in manufacturing. You can find the TopRepair Circuit Board Near Me option to find a good one.

Physical Damage

The first thing a PCB manufacturing business will look for if you bring in your PCBs for repair is physical damage. Drops, heat damage, water damage, collisions, dust, and even bugs can cause bodily harm. Physical damage to printed circuit boards is usually a result of external forces, such as a short circuit. Inherently flawed components or faulty design aren’t a factor in physical damage.

Before doing anything drastic with physical damage, you should check your PCB. Check for signs of water or liquid damage, such as swellings. Check for charred, scorched, or overheated parts as well. Also, inspect the PCBs for any damage that drops or impacts may have caused. Even if you aren’t planning on repairing a PCB yourself, it’s good to obtain a general idea of what’s going on. You might be shocked to learn that you don’t need to hire a PCB assembly business to correct the physical damage. If you want an expert you can search the TopRepair Circuit Board Near Me option.

Design flaws or low-quality parts

The PCB manufacturing process may have disastrous effects on printed circuit boards. PCB thickness, lousy soldering, and incorrect component placement can lead to poor performance or connectivity. A leading PCB assembly firm will be your best option if you need to replace your PCBs in this situation.

Trace Damage

It is possible to suffer trace damage due to normal wear and tear or fluid leakage. If the circuit board contains copper tracings, these can also wear down and lead to the death of the board. The Top Repair Circuit Board Near Meoption will help you to find a professional.

Defective Component on the PCB

Over time, PCB components will wear down and eventually die out due to the accumulation of wear and tear. One of the most frequently repaired PCB components is the capacitor, which is one of the more prone components to fail. In the PCB assembly, a capacitor regulates the flow of electrical current and aids in the smooth operation of the device. The electrolyte paste in most capacitors swells over time, preventing the capacitor from working correctly. Failed capacitors are the likely cause of any bulging components on your PCB, and you’ll need repair services from a competent PCB assembly firm.

Conclusion

While working with small, complex electronics like printed circuit boards, many things can go wrong. Fortunately, errors in PCBs tend to follow a set of predictable patterns. This means that if your printed circuit board fails, you will be able to fix it if you better understand these concerns. When you have PCB failure, keep the above mentioned ideas in mind as they could be helpful in your PCB manufacturing procedures.

Robot is a marketing manager at EZ Eletric. He has an interest in writing articles related to HVAC installation, maintenance, and repairs. The HVAC system has made our life convenient regardless of the climatic changes. Read Robot’s articles to know step-by-step installation guide for ceiling fan, smoke detector, lighting and electrical appliances in California as well as how to repair them in case of malfunctioning or breakdown.